years of

customer

loyalty

So many reasons to choose Van der Stähl Scientific

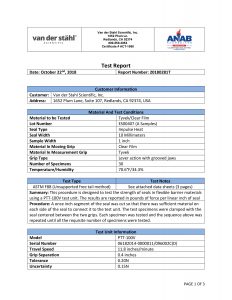

Our competent staff delivers our boutique services through our in-house ISO/IEC-17025 accredited laboratory that upholds the highest standard of quality control. Van der Stähl Scientific’s on staff certified packaging engineer is certified through the IOPP (the Institute of Packaging Professionals). All employees are required to understand quality systems and are CKF certified (Certified Kaizen Facilitators) to better manage the complicated process of medical device packaging validation. This assures you will receive competent technical support for the machines we offer. Choose a category below to learn more about why Van der Stähl Scientific is the clear choice for medical device packaging machinery.

Products

People

Services

Medical Pouch Sealers

We offer a wide range of patented medical packaging systems designed to meet FDA and ISO validation requirements.

Pouch Testing Systems

We provide the industry’s most advanced medical device pouch testing systems to better manage packaging recall risks.

Certified Training

Certify your maintenance and calibration staff through our online video training. Avoid recall risks with advanced learning.

Onsite services

Empirical Laboratory

We are an ISO/IEC-17025 accredited medical pouch testing laboratory, ready to serve your medical packaging validation.

Machine Calibrations

If you are an ISO-13485 company stay compliant with our calibration performed in our accredited ISO-17025 laboratory.

Machine Service

Count on highly trained quality system certified technicians to perform service and repairs on your precision machinery.

Certified Engineer

let’s explore the reason to choose van der stähl scientific

MACHINERY

Van der Stähl Scientific offers only the most technologically advanced packaging equipment; microprocessor controlled and designed to meet the rigors of the ISO 11607. But more than just the ability to meet the regulatory requirements for sterile packaging, our machines are built on a robust architecture that assures decades of dependable use.

We have had machinery, such as our MS-350, come into our service center operating perfectly, and these sealers have been in production for nearly 20 years. These sealers have literally created several million seals during their long life. We are astonished by how well these machines hold up; machines that are 15 years old perform just as they did the day they were liberated from their corrugated box.

Our goal is to also provide machine systems that utilize a minimal amount of mechanical componentry. Fewer parts mean fewer failures. The Van der Stähl Scientific machines that we offer are known throughout the industry as reliable workhorses.

We honestly do not know of another machine in our industry with such stellar performance. When you look at the cost of ownership matrix for our machinery the results are nothing short of stunning. Count on durable, long-performing machines from Van der Stähl Scientific.

RELIABILITY

PRICING

SAFETY

Also, with machines such as our MS 350, the sealer function can be actuated in a number of ways – either through the hand switch if it’s more ergonomic for the worker, or with a foot switch. The system can even be put in a semi-automated mode, in this mode of operation the operator is not required by any biomechanical action to activate the sealing jaws. The system timer can be set to automatically invoke the cycle at predetermined increments, this function can also pace workflow.

OUR EXPERTS

Having a certified technologist that is completely up to speed on the latest issues surrounding medical device packaging is an incredible benefit to your company. Van der Stähl Scientific works with thousands of engineers doing the very same job as you. We understand the regulatory climate that our machines will be involved in each day. This peer-style support helps to assure that the person at the other end of the phone can provide you valuable insight from the collective brain trust of the sterile device packaging community.

Our tech support is available Monday through Friday from 9am to 5pm through our toll free support line (800) 550-3854. When calling, select Option 3 and we’ll get your complicated questions answered quickly. For requests that are not time sensitive, you can also reach us through our contact form.

SERVICE

The point is when you call… we answer. Perhaps this is why so many companies have come back again and again to purchase products from Van der Stähl Scientific. It is indeed a unique mix, world-class technological prowess delivered with the warmth of a country store. Van der Stähl Scientific utilizes factory-trained technicians that truly understand every micro-component of the machinery we offer. Many of these skilled technicians not only service your machinery, but some are actually part of the group that creates the technology. We are thorough, well-trained professionals, committed to your satisfaction. It is this woven technological loop that assures the right person will be working on your machinery. Fast turnaround and competent service is the hallmark of Van der Stähl Scientific’s total customer care program.

Our service center is staffed with factory-trained technicians that truly understand your machinery. With more than 20 years experience servicing, repairing, and calibrating, our technicians are sure to quickly discover any issue with your machine and quickly repair it and get it back to your facility to get your company back online.

Many of our customers have our service department perform their annual “PM” “periodic maintenance.” Our robust, corrugated box that your machine comes in is designed to ship back to our company year after year. One such box has made the trip back and forth for nearly two decades for its annual calibration in its original box. Fill out the Service Request form and ship your machine back to us and we can perform a full service, and if need be, a full calibration in our ISO 17025 accredited laboratory. Fast, reliable, and competent – that’s the mantra of the Van der Stähl Scientific service center.

PARTS

At Van der Stähl Scientific, count on competent parts support. Van der Stähl Scientific is legendary for our ability to ship product in an expedited manner. Over the years we’ve had many customers ask us if they could pay an expedite fee in order to get their product earlier. Sorry, the answer is no. We do not accept expedite fees. We believe quite simply that providing exceptional customer service should not come with a fee. If we have the part in stock and we’re able to calibrate your machine, we’re ready to ship.

Just recently we had a customer who has several of our MS 350 medical pouch sealers who had an urgent run and needed a machine right away. Their goal was to get a machine in their cleanroom in a week in order to make up for lost time. They called us at approximately 11 a.m. and by 3 p.m. we had a calibrated machine on our docks, ready to ship to our waiting customer for next day arrival. We keep a solid buffer inventory of all of our popular machines in order to quickly perform for our valued customers.

METROLOGY

CONSULTING

TECHNOLOGY

With our new packaging systems in development, that will vacuum and burst test sterile pouches, we will be forging new paths that will have a ripple effect throughout sterile device packaging. Stay tuned for more exciting new technologies from Van der Stähl Scientific.

WARRANTY

If something doesn’t seem right, then you shouldn’t have to pay for it. And you simply won’t. Satisfaction is always guaranteed. If you’re unhappy with the Van der Stähl experience, call the CEO. Just call customer service and tell them to get the president. No employee firewalls between you and the president’s desk. We want to make you happy. Period. Van der Stähl Scientific has gained its reputation not through marketing and gimmicks, but by what we do day in and day out. We subscribe and closely follow a code of ethics. Thank you for the opportunity to serve you.

TESTING

So as you can see, there are many reasons to choose Van der Stähl Scientific. We could go on and on about other parts of our company and other functions that greatly benefit our customers, but we don’t want to brag. Need references from other customers who have benefited from our exceptional machinery and stellar customer service? Contact customer service at 800-550-3854 and we’ll be happy to put you in touch with a current customer so they can share their experiences with you about Van der Stähl Scientific.

Of course, we hope to earn your business. Sadly the term “earning your business” has become so generic it has lost all meaning. But when we say we wish to “earn your business” we mean it. We will do the work necessary to get your business; it’s our goal and our passion.

VALIDATION

We speak medical packaging validation

Our company founder and president comes from a micro-surgical device manufacturing background and he understands the challenges of medical device packaging compliance. While many packaging machine companies in our industry were born in general packaging, we have always been exclusively a medical device packaging machine provider.

We lead with patented, paradigm-shifting innovations like our MS-451 medical pouch sealer that integrates testing and inspection in order to thwart the distribution of failed seals.

Our ISO/IEC 17025 accredited laboratory supports each machine we sell with traceable calibrations and pouch testing.

Our staff of quality system certified technicians drive our machine service and calibration program. Our on-staff certified packaging team leader, Charlie Webb CPP, offers medical device packaging validation support for your installation qualification.

Years Established

1B +

sterile transfers annually

BEHIND OUR SEALERS A MEDICAL PACKAGING DREAM TEAM

Meet our Six Sigma master black belt, patented inventor and medical device packaging guru, contact Charlie for validation support.

The master of solutions, our Laboratory and Service Manager Cord Burnham guides our service, testing and calibration effort.

Hector is the master of media; he has a fresh eye on industrial design born from his time in the LA design district.

Our customers best friend, our General Manager Lisa Wassberg creates magic at every touch point for our medical device clients.

Sarah’s intuitive eye can solve machine issues with ease. She is Kaizen and Six Sigma certified and understands critical process.

The queen of customer support, Lou has skills throughout our organization from accounting, research, to customer experience.

Speak with a packaging expert

800-550-3854

Skip the salesman and speak with a certified packaging engineer like our support team leader Charlie A. Webb CPP, CKF. Charlie is a certified packaging engineer, a patented innovator and a six sigma master black belt with more than 20 years of sterile packaging experience. Fill out the form below and request a quote or give us a call, we would love to chat…