Pouch Sealers

Introduction to Pouch Sealers

At Van der Stahl Scientific, we specialize in providing state-of-the-art pouch sealers designed to meet the exacting standards of the medical device packaging industry. Our machines offer precise control and consistent sealing quality, crucial for maintaining the sterility and integrity of medical devices. With our deep understanding of the challenges involved in medical device packaging, we've developed a range of solutions to help our customers achieve compliance and ensure product safety.

Understanding Pouch Sealers

Pouch sealers play a pivotal role in the medical device packaging process, ensuring that products are securely sealed in sterile barrier systems. These machines apply heat and pressure to seal the pouch, creating a barrier against contaminants. Our range includes various models, such as impulse pouch sealers and rotary pouch sealers, each designed to cater to different production needs and pouch materials.

Impulse vs. Constant Heat Sealers

The choice between impulse sealers and constant heat sealers depends on the specific requirements of the medical device packaging task at hand. Impulse sealers, which heat up only during the sealing process, are ideal for sealing plastic and laminated pouches without damaging the contents. Constant heat sealers, on the other hand, maintain a constant temperature, making them suitable for materials that require sustained heat for a successful seal.

Choosing the Right Pouch Sealer

Choosing the correct pouch sealer is essential for ensuring packaging integrity. Factors to consider include the type of material, the size of the pouch, and the speed of production required. At Van der Stahl Scientific, we offer a consultative approach to help you select the most appropriate sealer for your needs, considering these factors and more, to optimize your packaging process.

Innovative Solutions in Pouch Sealing

Our commitment to innovation has led us to develop advanced pouch sealers that provide unmatched reliability and efficiency. For example, our rotary pouch sealers are designed for high-speed operations, ensuring consistent seals at faster rates. This is particularly beneficial for large-scale production environments where throughput and reliability are paramount.

In addition to our standard machines, we offer custom solutions tailored to the unique requirements of our clients. Whether you need a machine with specific dimensions or one that can handle an unusual material, our team has the expertise to design a solution that meets your needs.

Validation and Compliance

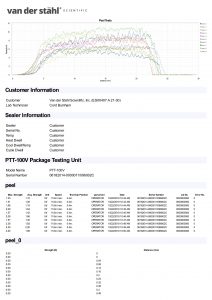

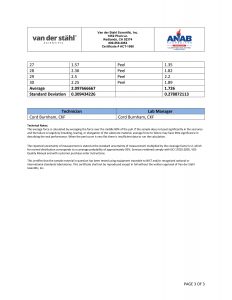

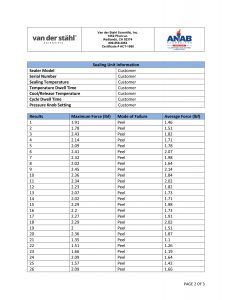

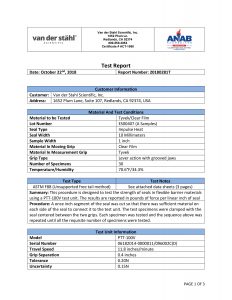

Ensuring compliance with regulatory standards is a top priority for medical device manufacturers. Our pouch sealers are designed with this in mind, featuring precise control systems and thorough documentation to support the validation process. We also offer validation services and calibration plans to assist in meeting FDA and other regulatory requirements, making the validation process as seamless as possible.

Unmatched Customer Support

At Van der Stahl Scientific, we understand the importance of reliable customer support. Our team of experienced professionals is available to provide comprehensive training, troubleshooting assistance, and maintenance services. We're here to ensure you get the most out of your pouch sealing equipment, with minimal downtime and maximum operational efficiency.

From the Founder's Desk

Coming from a background in micro-surgical device manufacturing, I've experienced firsthand the challenges of ensuring product sterility and packaging integrity. This insight has shaped our approach at Van der Stahl Scientific, driving us to develop pouch sealers that address the critical needs of the medical device industry. Our goal is to provide not just machines, but complete solutions that enhance the reliability and efficiency of your packaging operations.

Customer Testimonials

Our clients are our best advocates, and their feedback underscores the value of our products and services. From the dependability of our pouch sealers to the professionalism of our support team, customer testimonials highlight the positive impact our solutions have on their operations. We take pride in these stories, as they reflect our commitment to quality and customer satisfaction.

Additional Resources and Support

To further support our customers, we offer a range of resources including machine training, calibration plans, and a well-stocked parts department. Our aim is to provide you with everything you need to maintain your equipment and meet your packaging requirements efficiently. With Van der Stahl Scientific, you have a partner dedicated to the success of your medical device packaging operations.

Conclusion

In conclusion, pouch sealers are critical to ensuring the safety and efficacy of packaged medical devices. At Van der Stahl Scientific, we offer a range of pouch sealing solutions that meet the stringent requirements of the medical device packaging industry. With our focus on innovation, quality, and customer support, we are committed to providing you with the equipment and services you need to achieve successful packaging outcomes. Let us be your partner in navigating the complexities of medical device packaging compliance.

What distinguishes impulse pouch sealers from constant heat sealers, and when should each be used?

Impulse pouch sealers and constant heat sealers cater to different needs within the medical device packaging industry, and understanding their unique capabilities is key to selecting the right equipment. Impulse sealers heat up only when they are activated to seal a pouch, which makes them incredibly efficient for sealing plastic and laminated materials. They're the go-to choice when the goal is to minimize heat exposure and prevent any potential damage to the sensitive medical devices inside the pouches. Imagine you're packaging a heat-sensitive surgical instrument; an impulse sealer ensures the item is not compromised by the sealing process.

On the other hand, constant heat sealers maintain a set temperature throughout their operation. They're ideal for materials that require consistent heat to achieve a strong and durable seal. This can be particularly beneficial when dealing with thicker or more robust materials that need that sustained exposure to ensure the pouch is fully sealed. So, if you're working with heavy-duty pouches that encase larger medical equipment, a constant heat sealer might be your best bet.

Choosing between the two often comes down to understanding the specific packaging requirements of the medical device in question. Do you prioritize minimizing heat exposure due to the sensitivity of the device, or is your primary concern ensuring a durable seal for robust packaging? Reflecting on this question can help guide the selection process.

How can one effectively choose the right pouch sealer for their medical device packaging needs?

Choosing the right pouch sealer is more of an art than a science, requiring a balance between technical specifications and the unique needs of each medical device. Considerations include the type of material you're sealing, the size and volume of pouches, and the speed at which your production line operates. Let's say you're sealing smaller, delicate devices in high volumes; an impulse sealer known for its quick operation and minimal heat exposure might be ideal. Conversely, for larger, more durable items that may not be as sensitive to heat, a constant heat sealer could provide the robust seals needed.

Another important factor is engaging with the experts. At Van der Stahl Scientific, our consultative approach is designed to navigate these decisions with you. We consider not just the immediate needs but also how a sealer fits into your broader operational goals. It's about finding a machine that not only meets your current requirements but also supports your future growth and development.

Moreover, don't underestimate the value of customization. Sometimes, off-the-shelf options might not quite fit the bill, and that's where our ability to tailor solutions comes into play. Have you ever encountered a packaging challenge that seemed unique to your operation? That's where a customized approach can make all the difference.

What innovations in pouch sealing technology are currently impacting the medical device packaging industry?

The landscape of medical device packaging is continuously evolving, driven by advances in pouch sealing technology. One of the most significant innovations we've seen is the development of rotary pouch sealers designed for high-speed operations. This technology is a game-changer for large-scale production environments where efficiency and reliability are paramount. Imagine a scenario where demand suddenly spikes, and you need to ramp up production quickly without sacrificing quality. In such cases, the speed and consistency offered by rotary sealers can help keep operations running smoothly while ensuring each seal meets stringent quality standards.

Customization is another area where innovation is making a big impact. The capability to design pouch sealers tailored to the unique requirements of specific medical devices or packaging materials offers unparalleled flexibility. This ensures that even the most challenging packaging needs can be met with precision and efficiency. Whether it's a sealer that can handle unusual material combinations or one that fits into a compact production space, the potential to customize solutions opens up new possibilities for manufacturers.

Lastly, the integration of advanced control systems in pouch sealers is enhancing both operability and compliance. Being able to monitor and adjust sealing parameters with precision means that manufacturers can achieve consistent, high-quality seals every time. This level of control is particularly crucial in the medical device industry, where packaging integrity directly impacts patient safety.

How does Van der Stahl Scientific address the compliance challenges faced by medical device manufacturers in pouch sealing?

Compliance is at the heart of everything we do at Van der Stahl Scientific. We understand that for our clients, ensuring their packaging meets regulatory standards is not just about ticking a box; it's about guaranteeing the safety and efficacy of medical devices. Our pouch sealers are designed with this priority in mind, featuring precise control systems and comprehensive documentation to facilitate the validation process.

We take a proactive approach to compliance, offering validation services and calibration plans tailored to the unique needs of the medical device packaging industry. Our support extends beyond just supplying equipment; we guide our clients through the validation process, making it as seamless as possible. Picture a scenario where a regulatory audit is looming, and documentation is needed to prove compliance. Our team would be on hand to provide the necessary records and support, ensuring that our clients not only pass inspections but do so with confidence.

Our commitment to maintaining the highest standards of quality and reliability in our products is reflected in our ISO 17025 accredited laboratory. This accreditation is a testament to our rigorous testing and calibration protocols, which ensure that every sealer we provide meets the stringent requirements of the medical device packaging industry.

Remember, compliance is an ongoing journey, not a one-time event. How does your organization currently handle packaging validation, and could it benefit from a more integrated approach?

Resources

- U.S. Food & Drug Administration (FDA) - The FDA website provides information on regulatory standards and requirements for medical device packaging compliance.

- International Organization for Standardization (ISO) - The ISO website offers international standards relevant to medical device packaging and quality management systems.

- World Health Organization (WHO) - The WHO website provides guidelines on health and regulatory matters, including medical device packaging safety.

- National Center for Biotechnology Information (NCBI) - NCBI offers research and information on medical device packaging materials and techniques.