Rotary Sealer

Introduction to Rotary Sealer

At Van der Stahl Scientific, our journey into the realm of sterile medical device packaging has led us to an intimate understanding of the critical role played by sealing technology. Among these, the rotary sealer stands out for its precision, reliability, and efficiency in ensuring that medical devices reach their destination in a sterile condition. It's essential to grasp not only what a rotary sealer is but why it has become a cornerstone in the medical packaging industry.

Understanding Rotary Sealers

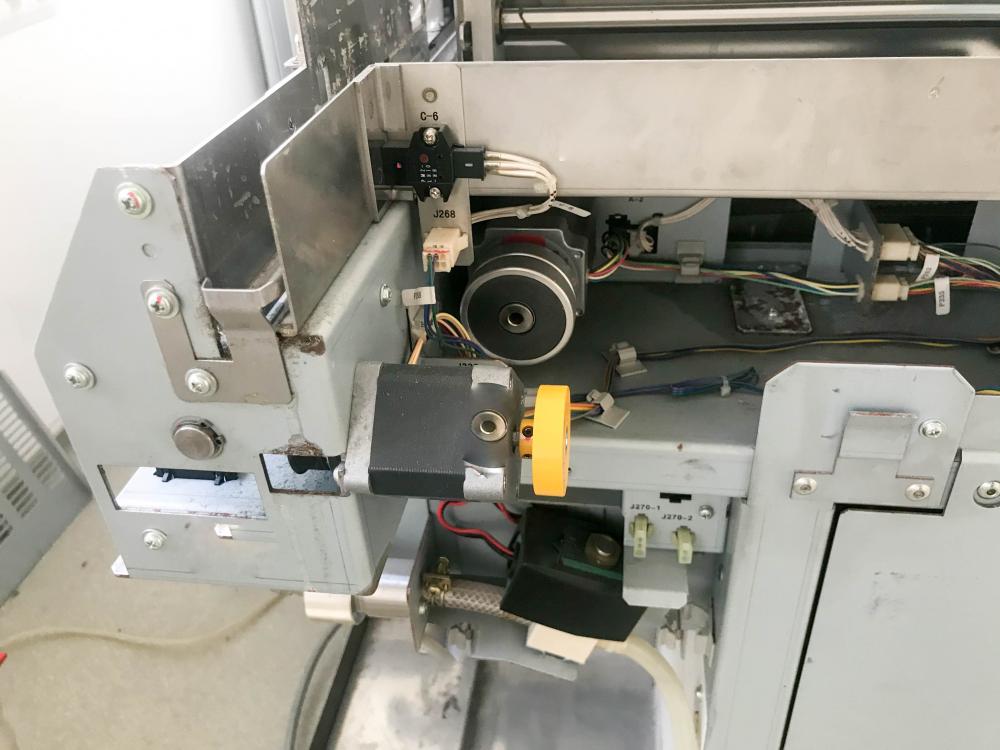

What is a Rotary Sealer?The term rotary sealer refers to a sophisticated device designed to create airtight seals on flexible pouches and bags, a process crucial in maintaining the sterility of medical devices. Unlike other sealing methods, a rotary sealer employs a continuous sealing mechanism, ensuring high-volume output without sacrificing quality or integrity.

Why Choose a Rotary Sealer?In the medical device packaging realm, a rotary sealer is not just a preference; it's a necessity. Its ability to maintain consistent pressure and temperature across each seal ensures that each package meets stringent regulatory standards for sterility. This peace of mind is invaluable, especially when considering the potential consequences of compromised device sterility on patient safety.

Benefits of Using a Rotary Sealer

The advantages of integrating a rotary sealer into your packaging process are manifold. From operational efficiency to compliance with regulatory standards, the benefits underscore why this technology is pivotal in the medical device packaging industry.

- Consistency: Rotary sealers deliver uniform seal integrity, crucial for ensuring the sterility of packaged medical devices.

- Efficiency: Designed for high-volume operations, they support continuous processing, reducing downtime and increasing productivity.

- Compliance: Meeting regulatory standards is non-negotiable in medical device packaging. Rotary sealers are built to comply with rigorous industry requirements.

Rotary Sealer Applications

In the vast landscape of medical device packaging, rotary sealers prove their worth across a broad spectrum of applications. From surgical instruments to diagnostic kits, the need for reliable sealing technology is universal.

Medical Devices and PharmaceuticalsRotary sealers provide the seal integrity necessary for various medical products, ensuring that they remain sterile and safe for patient use. This includes everything from single-use surgical instruments to critical pharmaceuticals.

Choosing the Right Rotary Sealer

Considerations for SelectionSelecting the correct rotary sealer requires careful consideration of your specific needs. Key factors to evaluate include the type of materials being sealed, the desired speed of the sealing process, and the regulatory standards that the sealer must meet.

Van der Stahl Scientific's OfferingsOur range of rotary sealers is designed to cater to the diverse needs of the medical packaging industry, ensuring that you can find the perfect match for your operation. With our commitment to quality and compliance, you can trust our solutions to meet, and exceed, your expectations.

Innovations in Rotary Sealing

The landscape of rotary sealing is ever-evolving, with technological advancements continually raising the bar for what's possible. At Van der Stahl Scientific, innovation is at the heart of what we do. Our rotary sealers incorporate the latest in sealing technology, ensuring unparalleled precision and reliability.

Our Commitment to Quality

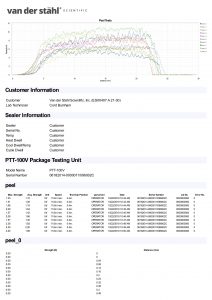

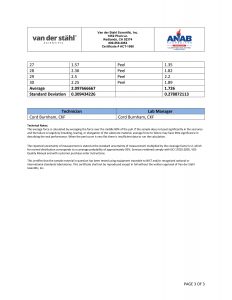

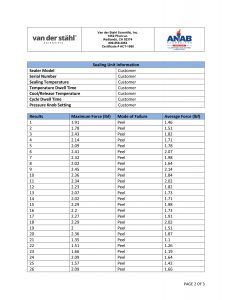

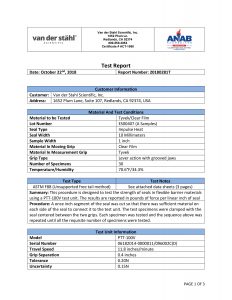

Quality is not just a buzzword at Van der Stahl Scientific; it's the foundation of our brand. Our ISO 17025 accredited laboratory is a testament to our unwavering commitment to delivering products that not only meet but exceed industry standards. Our team of experienced professionals, including six-sigma certified technicians and packaging experts, is dedicated to ensure that every rotary sealer we offer represents the pinnacle of quality and performance.

Customer Support and Training

Choosing a rotary sealer is only the beginning. We believe in supporting our customers every step of the way, from initial selection to ongoing maintenance. Our comprehensive training programs ensure that your team can maximize the benefits of our technology, while our responsive customer service team is always on hand to address any questions or concerns.

Conclusion

As we look to the future, the importance of reliable, efficient, and regulatory-compliant sealing technology in the medical device industry cannot be understated. A rotary sealer, with its precision and consistency, represents a critical component of the packaging process. At Van der Stahl Scientific, we're not just selling machines; we're providing solutions that protect and preserve the integrity of medical devices, ultimately safeguarding patient health. With our commitment to innovation, quality, and customer support, we are proud to be at the forefront of the medical device packaging industry.

What is the difference between heat sealer and impulse sealer?

Well, let me paint you a picture to illustrate the differences between a heat sealer and an impulse sealer, as this is a question we encounter frequently at Van der Stahl Scientific. Imagine you're sealing a bag of freshly roasted coffee beans to preserve their aroma and flavor. Using a heat sealer, you'll apply constant heat to the bag's opening, creating a robust seal. This method is fantastic for materials that can withstand continuous heat without degrading.

On the flip side, an impulse sealer operates differently. It delivers a rapid pulse of heat through a heating element, sealing the bag without transmitting excessive heat to the surrounding area. This is particularly useful for sensitive materials that might melt or warp under sustained heat. It's like giving a quick, high-intensity workout to the seal area, ensuring it's sealed tight without affecting the rest of the bag's integrity.

So, in summary, the key difference boils down to the method and duration of heat application. Whether you choose a heat sealer or an impulse sealer depends on the specific requirements of the materials you're working with. Have you considered which sealing technique might best suit your needs?

What are the different types of sealer machines?

Exploring the variety of sealer machines available in the market is akin to walking through a garden of tools, each designed to address specific challenges and applications. At Van der Stahl Scientific, we've worked with a broad spectrum of sealing devices, and I'm excited to share insights into some of the main types:

- Impulse Sealers: Ideal for small to medium volumes and suitable for a wide range of materials. These sealers deliver heat in short bursts, minimizing the heat exposure to the product.

- Continuous Band Sealers: As the name suggests, these machines seal products continuously, making them perfect for high-volume needs. They're versatile, handling various bag materials with ease.

- Rotary Sealers: Our specialty, designed for precision and efficiency in medical device packaging. They provide consistent sealing for ensuring sterility in medical environments.

- Vacuum Sealers: These remove air before sealing, vastly extending the shelf life of food and medical products by preventing oxidation.

Choosing the right sealer involves considering your volume, material type, and specific industry needs. Have you identified the sealer type that aligns with your operational goals?

What is the difference between horizontal and vertical band sealer?

Let's navigate the nuances between horizontal and vertical band sealers, as each serves unique purposes based on the orientation of the sealing process. Imagine you're packing a series of finely ground coffee. A horizontal band sealer would be your ally here, laying the bag flat to ensure the fine particles stay evenly distributed and don't interfere with the sealing process.

In contrast, if you're dealing with liquids or granules that risk spilling, a vertical band sealer steps into the spotlight. This setup allows you to feed the bag upright, preventing spillage and ensuring a clean, secure seal. It's like choosing between laying down to zip up a suitcase full of clothes or standing it upright - the contents and their behavior dictate the best approach.

Ultimately, the choice between a horizontal and vertical band sealer hinges on the nature of your product and how gravity affects its positioning during the sealing process. Have you encountered situations where one orientation would clearly benefit over the other?

What is a continuous sealer?

Envision a continuous sealer as a diligent assembly line worker, capable of sealing packages one after another without pause. This type of sealer is designed for efficiency and can handle a high volume of products with ease. It operates by moving the product along a conveyor belt, applying heat to seal the package as it travels. This is particularly useful for businesses that require rapid, consistent sealing of bags or pouches, like those in the food industry or high-volume medical device packaging.

The continuous sealer is a game-changer for operations looking to scale up their packaging process. By streamlining the sealing phase, it not only increases productivity but also ensures uniform quality across all sealed products. Have you considered how a continuous sealer could transform your packaging workflow?

What are the latest innovations in rotary sealing technology?

In the world of rotary sealing, innovation never sleeps. At Van der Stahl Scientific, we're at the forefront, integrating advancements that enhance precision, efficiency, and reliability. One exciting development is the incorporation of intelligent control systems. These systems monitor and adjust sealing parameters in real-time, ensuring each seal is perfect, even under varying operational conditions.

Another breakthrough is in materials science, with the introduction of more resilient sealing bands that withstand higher temperatures and wear, extending the machine's lifespan and reducing downtime. Additionally, we're exploring the integration of IoT (Internet of Things) capabilities, enabling remote monitoring and maintenance, which ensures peak performance and anticipates needs before they become problems.

These innovations not only push the boundaries of what's possible in sealing technology but also align with our commitment to offering solutions that meet the evolving needs of the medical device packaging industry. How do you see these advancements shaping your packaging operations?

How do you choose the right material for sealing?

Choosing the right material for sealing is like selecting the right key for a lock. It requires understanding both the characteristics of the material and the requirements of the product being sealed. At Van der Stahl Scientific, we consider several factors, such as the material's heat resistance, barrier properties, and compatibility with the product.

For instance, polyethylene is widely used for its versatility and strong sealability, making it suitable for a range of products. On the other hand, foil laminates offer excellent barrier properties against moisture and oxygen, ideal for sensitive medical devices or pharmaceuticals.

The choice also depends on the sealing technology you're employing. Certain materials work better with impulse sealers, while others are more suited for continuous or rotary sealers. Engaging with an expert to understand the nuances of each material and its interaction with sealing methods can unlock optimal packaging performance. Have you considered the specific properties of your packaging material in relation to the sealing process?

Resources

- Food and Drug Administration (FDA): The FDA website provides information on regulations and guidelines for medical device packaging in the United States. Visit the FDA website.

- World Health Organization (WHO): The WHO offers global standards and recommendations for medical device packaging and sterilization. Visit the WHO website.

- Centers for Disease Control and Prevention (CDC): The CDC provides resources on infection prevention and control in healthcare settings, including information on packaging and sterilization. Visit the CDC website.

- National Institutes of Health (NIH): The NIH offers research and resources on medical device development, including information on packaging and sealing technologies. Visit the NIH website.